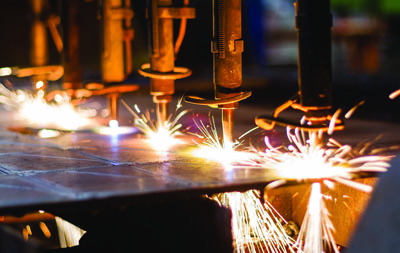

Source Metals provides quality flame cutting as a metal cutting service with quick turnaround times. Our flame cutting department uses Messer CNC controlled machines that provide accuracy as well as speed. Partnered with operators fully equipped with tools and training needed to achieve close tolerance and quality burnouts.

Flame cutting’s simple operation is the leading reason it continues to serve as a mainstay of the plate processing industry. Simple operation equals lower production cost which means lower pricing for our customers. This cutting method enables a cost effective way to make steel partial from bridges to industrial equipment.

The Machines

(2) CNC Pattern Torch Burning System

- 8 oxy acetylene torch heads

- 10′ x 44′ cutting area

- Burny®3 CNC control

The Capabilities

- Steel plate can burn up to 8 inches thick

- Simple and complex shapes can be cut from carbon and alloy plates

- Our operators are fully equipped with the tools and training for close tolerance burnout

- Standard tolerance of +1/16” to + ½”

The Process

Flame cutting is a process that uses a neutral flame to melt and cut metal parts. The use of oxygen and fuel in the flame cutting process is also known as Oxy fuel cutting.

Oxy fuel processes use fuel gases and oxygen to preheat the metal to a cherry hot color. Once the proper temperature is reached then pure oxygen is added. The cutting torch heats the metal to start the process and is not intended to melt the metal but to bring it to it’s ignition temperature.

The oxygen stream reacts with the metal, gets oxidized and produces heat. The heat is what continues the cutting process.

The Benefits

- Inexpensive method of steel cutting

- Superior dimensional tolerances

- Faster production times than sawing or total machining

The Results

| What are your flame cutting needs? Call us at 713-466-7310 or fill out the form below. |